Electron Beam Welding

EB Fusion provides a unique EBW service to industry Australia-wide, in conjunction with high-precision CNC turning and engineering capabilities, with a specific focus on metals and engineering thermoplastics such as polyether ether ketone (PEEK), polyphenylene sulphide (PPS) and polytetrafluoroethylene (PTFE).

Characteristics

Maximum Weld Penetration

Narrow Fusion Zone

Inert Atmosphere (Vaccum)

Near Parent Mental Strength

Minimal Distortion

Benefits

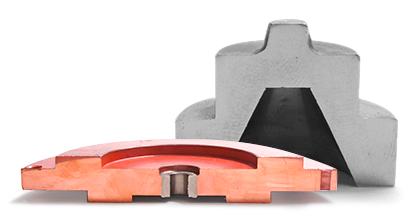

The advantages of EBW include a high power density with very low overall heat input and therefore minimal distortion. EB welded parts require a minimal, if any, post-weld machining and unlike other fusion welding processes, they require no shielding gases. The weld quality is exceptional, with deep penetration and a narrow fusion zone resulting in near parent metal strength.

- Maximum weld penetration with the least amount of heat input.

- Minimal distortion.

- Narrow heat affected zone (HAZ).

- High welding speed.

- EBW often reduces the need for secondary operations.

- Repeatable precision micro-welding.

- A clean, strong, homogenous weld is produced under vacuum without filler material.

- The vacuum environment eliminates atmospheric contaminants in the weld.

- Exotic alloys and dissimilar materials can be welded.

- EBW frequently yields 0% scrap rate.

- Extreme precision and reproducibility due to computer controlled process.

- EBW can be employed to salvage and repair both old and new components.

Limitations

- The necessity for a vacuum chamber.

- The volumetric capacity of the vacuum chamber and the associated fixtures.

- The vacuum chamber dimensions at EB FUSION measures 300mm(H) x 300mm(W) x 300mm(D), with a range of chamber extensions developed for specific job requirements.