Laser Processing

Laser processing involves using a laser beam to alter the surface of a material through thermal effects, including laser welding, laser cutting, surface modification, laser marking, laser drilling, and microprocessing.

The laser beam can be used to perform various tasks, such as punching, cutting, scribing, welding, and heat treatment, on different materials.

The laser is capable of processing any material, and it plays an indispensable role in precision and specialized processing and manufacturing, especially in special circumstances and with special materials.

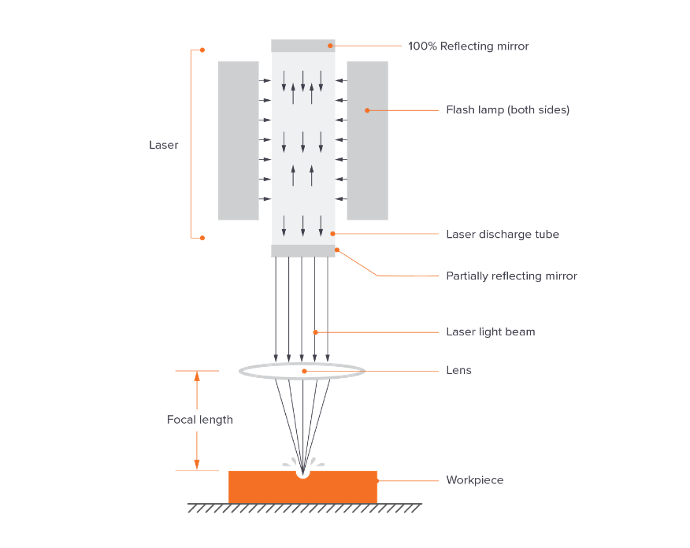

How it works

Laser processing involves using a laser beam to alter the surface of a workpiece through high energy irradiation. This results in removal of material, melting, or modification of surface properties. The process is non-contact, meaning the tool does not generate resistance by grinding against the workpiece surface, making it a fast and efficient method.

Additionally, the energy and speed of the laser beam can be adjusted, allowing for versatile applications to various levels and ranges.

Laser Processing Features

Non-Contact Processing

As it is non-contact processing, and the energy of the high-energy laser beam and its moving speed are adjustable, it can be used for a variety of processing purposes.

Variety of Materals

It can process a variety of metal and non-metallic materials, especially those with high hardness, brittleness, and melting point.

High Precision

This machining process produces object of very high precision. And most of the object does not require additional finishing. The laser beam energy density is very high during processing, making it fast and highly localized, with minimal impact on areas not exposed to laser irradiation.

Laser Processing Application Examples

Automotive

Medical

Aerospace

Electrical

Advantages of Laser Processing

- High laser power density allows for the rapid rise in temperature and melting or vaporization of the workpiece, even for materials with high melting points, high hardness, and brittleness.

- The laser head does not come into direct contact with the workpiece, eliminating the issue of wear during processing.

- The workpiece is free from forces and is not easily contaminated.

- The workpiece can be processed while in motion or inside a sealed glass shell.

- The divergence angle of the laser beam can be less than 1 millionth of an arc, with a spot diameter as small as a few microns and an action time of nanoseconds to picoseconds. Meanwhile, high-power laser continuous output power can reach kilowatts to ten kilowatts, making the laser suitable for both precision microprocessing and large-scale material processing.