Precision Machining

How it works

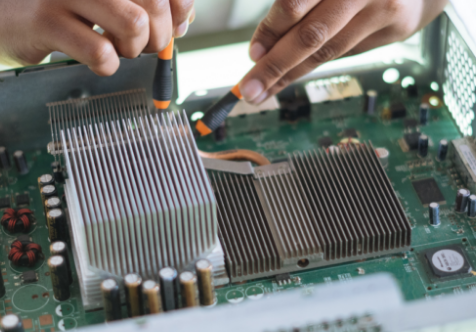

Precision Machining is a process to remove material from a workpiece while holding close tolerance finishes. The precision machine has many types, including milling, turning and electrical discharge machining. Advanced precision machining is performed by an EDM machine. A precision machine today is generally controlled using a Computer Numerical Controls (CNC).

Precision machining contributes parts and pieces from space shuttle pencils. Almost all metal products use precision machining, as do many other

materials such as plastic and wood. These machines are operated by specialized and trained machinists.

The precision machining process involves a cutting tool that removes material from the workpiece. In order for the cutting tool to do its job, it must be moved in directions specified to make the correct cut. This primary motion is called the “cutting speed.” The workpiece can also be moved, known as the secondary motion of “feed.” Together, these motions and the sharpness of the cutting tool allow the precision machine to operate.

Benefits of Precision Machining

Tight Tolerances

Tolerance is also known as dimensional accuracy. It refers to the slight deviation in the size of a machined part from its CAD blueprints. CNC precision machining uses specialized processes and cutting tools to reduce the tolerances to the minimum values possible. This leads to higher accuracy of the parts compared to the original blueprints.

High Accuracy

The tight tolerances directly infer that the final product created by precision machining will have high accuracy. Precision machining is generally performed for parts that require interworking with other parts and components. Therefore, high accuracy becomes essential for these particular parts to work flawlessly in later stages.

High Repeatability

The concept of repeatability is one of the important foundation stones for modern manufacturing industries. Every part manufactured by a process is intended to look like every other part for the end user. Any deviation from this reproduction is often considered a defect. Precision machining is appealing in this regard. With high precision CNC machining, every part is identical to the original with negligible deviations.

Low Production Costs

Due to the lack of deviations in precision machining, there are fewer defective productions. So the process leads to a lower rejection rate of parts. Therefore, the cost of materials is lower. Additionally, being an automated computer-aided manufacturing process results in reduced labor costs. The combined reduction in labor costs and material costs means that the production costs of CNC machining are lower than any alternatives.

Speed and Efficiency

A CNC machine replaces human labor with computer numerical control systems and eliminates the human error risk factor involved in the cutting processes. Workers can be transferred to more skill-intensive roles such as CNC design operations.

Precision Machining Application Examples

Automotive

Medical

Aerospace

Electrical

Suitable Materials for Precision Machining

Precision machining works on hundreds of different metals, plastics, and other composite materials. Here is a list of some common materials that undergo precise machining:

Metals and Alloys

- Aluminum

- Bronze

- Brass

- Copper

- Titanium

- Steel

- Stainless Steel

- Carbon Steel

- Tool Steel

- Exotic Alloys

Plastics and Other Non-metals

- Polyamide (PA)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

- Glass

- Graphite